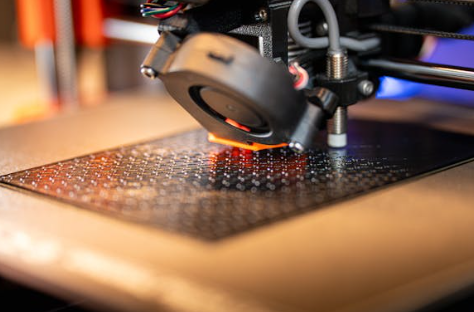

3D printing, once considered a novelty for hobbyists and prototype labs, has quietly become one of the most transformative tools in modern industries. While it’s been used for years in manufacturing and design, its deeper impact is being felt in two crucial areas: medicine and construction.

What makes 3D printing so powerful in these fields isn’t just the ability to replicate objects—it’s the ability to customize, iterate, and build on demand. Whether it’s a life-saving implant or an entire house, this technology is pushing boundaries not through hype, but through utility.

Precision Meets Healing: 3D Printing in Medicine

The human body is incredibly complex. No two people are exactly alike, which makes treating patients a challenge—especially when it comes to things like implants, prosthetics, or surgical planning. Traditional manufacturing is built around uniformity. 3D printing flips that model.

Custom Implants and Prosthetics

In the past, creating a medical implant—like a jawbone or spinal support—meant adapting the patient to the device. Now, with 3D scanning and printing, it’s the other way around. Surgeons can use detailed imaging (CT scans, MRIs) to create implants that match a patient’s anatomy down to the millimeter.

The result is not only a better fit but also fewer complications and faster recovery. For example, in reconstructive surgery after trauma or cancer, doctors can print titanium implants shaped precisely to fill a defect or support delicate structures.

Prosthetics, too, have been transformed. Instead of costly, mass-produced limbs, patients—especially children who outgrow devices quickly—can receive customized, lightweight prosthetics tailored to their needs and lifestyle, often at a fraction of the price.

Bioprinting and Tissue Engineering

Perhaps the most talked-about frontier in medical 3D printing is bioprinting—using cells and bio-inks to print tissues or organs. While we’re still years away from printing a fully functional human heart, progress has been real and measurable.

Labs have already produced small patches of tissue, blood vessels, and cartilage that can be used in research or as scaffolds to help the body regenerate. The long-term hope is to reduce organ transplant shortages and eliminate the risks of rejection by using a patient’s own cells.

Surgical Tools and Training

Another quiet but important use is in surgical preparation. Doctors can print a replica of a patient’s organ—say, a heart with a rare malformation—and use it to plan a complex procedure before setting foot in the operating room. It’s not just a visual aid; it’s a dry run that can mean the difference between success and failure.

Even tools themselves—like clamps, retractors, or surgical guides—can be printed quickly, cheaply, and sterilized for use in operating rooms, especially in low-resource settings.

Reimagining the Built Environment: 3D Printing in Construction

The idea of printing a house sounds like science fiction, but it’s already happening—and not just in experimental projects. Around the world, companies are using massive 3D printers to build walls, foundations, and entire structures out of concrete-like materials, directly on-site.

Speed and Efficiency

One of the most compelling advantages of 3D printing in construction is speed. A small house can be printed in 24 to 48 hours of machine time. That doesn’t mean someone moves in the next day—plumbing, electrical, and finishes still take time—but the core structure can be up in days rather than weeks.

This speed is a game-changer in areas facing housing shortages or recovering from disasters. Entire communities could be rebuilt faster, with fewer materials wasted, and with more design flexibility than traditional construction allows.

Cost and Material Use

Because 3D printing deposits material only where it’s needed, there’s far less waste. Complex architectural shapes that would be expensive or impossible to build with conventional methods can be printed easily. This opens the door to new design possibilities—curved walls, organic forms, and modular structures that aren’t limited by the constraints of mold-based building.

Materials vary. Some printers use concrete mixes reinforced with fibers or additives for strength. Others experiment with local soil, recycled materials, or lightweight foams. While not all are suitable for every climate or code requirement, the range is expanding quickly.

Customization at Scale

In traditional construction, customization often means higher costs. But in 3D printing, changing a design can be as simple as adjusting a file. This means that housing developments could feature unique layouts tailored to the landscape, the climate, or the specific needs of residents—without sacrificing efficiency.

For example, in a remote village, one home might be designed with larger windows for ventilation, while another might have thicker walls for insulation. The printer doesn’t care about the difference—it just follows instructions.

Barriers and Limitations

Despite the promise, 3D printing in both medicine and construction isn’t without its limits.

In medicine, regulatory approval is a significant hurdle. Implants and bioprinted tissues must undergo rigorous testing before they can be widely used. There’s also the question of long-term outcomes—how printed materials hold up in the body over years or decades.

In construction, challenges include building codes, local regulations, and the need for trained personnel to manage printers and finish the work. 3D printing can build walls, but humans still need to install wiring, HVAC systems, roofing, and interiors.

There’s also the matter of scale. While small homes and buildings are feasible, printing skyscrapers is another matter entirely—for now.

The Road Ahead

By the time we hit the middle of this century, the line between digital and physical manufacturing will be blurrier than ever. In medicine, a patient might walk into a hospital, get scanned, and leave with a printed bone graft or even a new ear. In construction, entire neighborhoods could be built by a fleet of printers, each following a shared blueprint adapted to local needs.

What’s striking is how 3D printing shifts the center of power from factories and supply chains to design and data. Instead of waiting weeks for a part to be delivered, a technician might print it on-site in hours. Instead of mass-producing generic tools or devices, we can build exactly what’s needed, when it’s needed.

It’s not about creating a futuristic world—it’s about refining how we meet real human needs, more directly and more thoughtfully.